Industrial Plastic Shredders for Sale

Plastic shredders for sale from BCA Industries are built for tough industrial applications. We manufacture stationary, portable and mobile plastic recycling shredders designed to handle packaging waste, molded parts and production scrap with consistent results. Each system simplifies material handling, reduces processing time and supports downstream recycling in plastics and other industries. Request a quote today to find the right plastic shredder for your operation.

Industrial Plastic Recycling Machines for Sale

BCA engineers plastic recycling machines for efficient material reduction and long-term durability. Our inventory includes stationary, portable and mobile plastic shredders for sale designed to handle a wide range of plastic waste, from bulky production scrap to lightweight packaging. Whether you need a standalone plastic shredder or a complete recycling solution, BCA delivers industrial-grade performance for every operation.

Types of Plastic Shredders We Sell

BCA Industries designs plastic shredders to meet the demands of high-volume waste processing operations nationwide. Our machines handle everything from bulky molded scrap to lightweight film and packaging materials. Choose from stationary and portable units built to simplify plastic reduction and deliver consistent sizing in fewer passes:

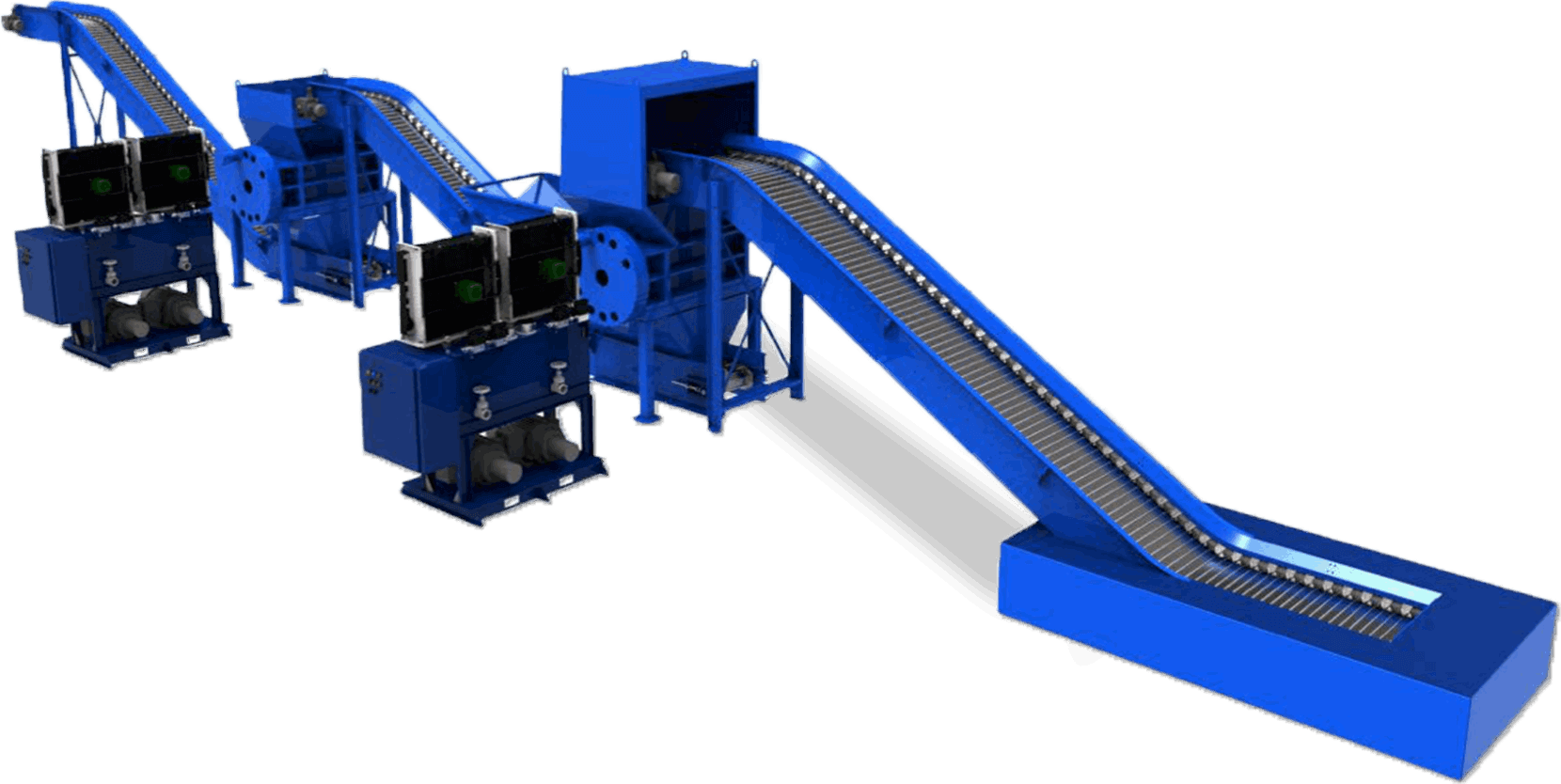

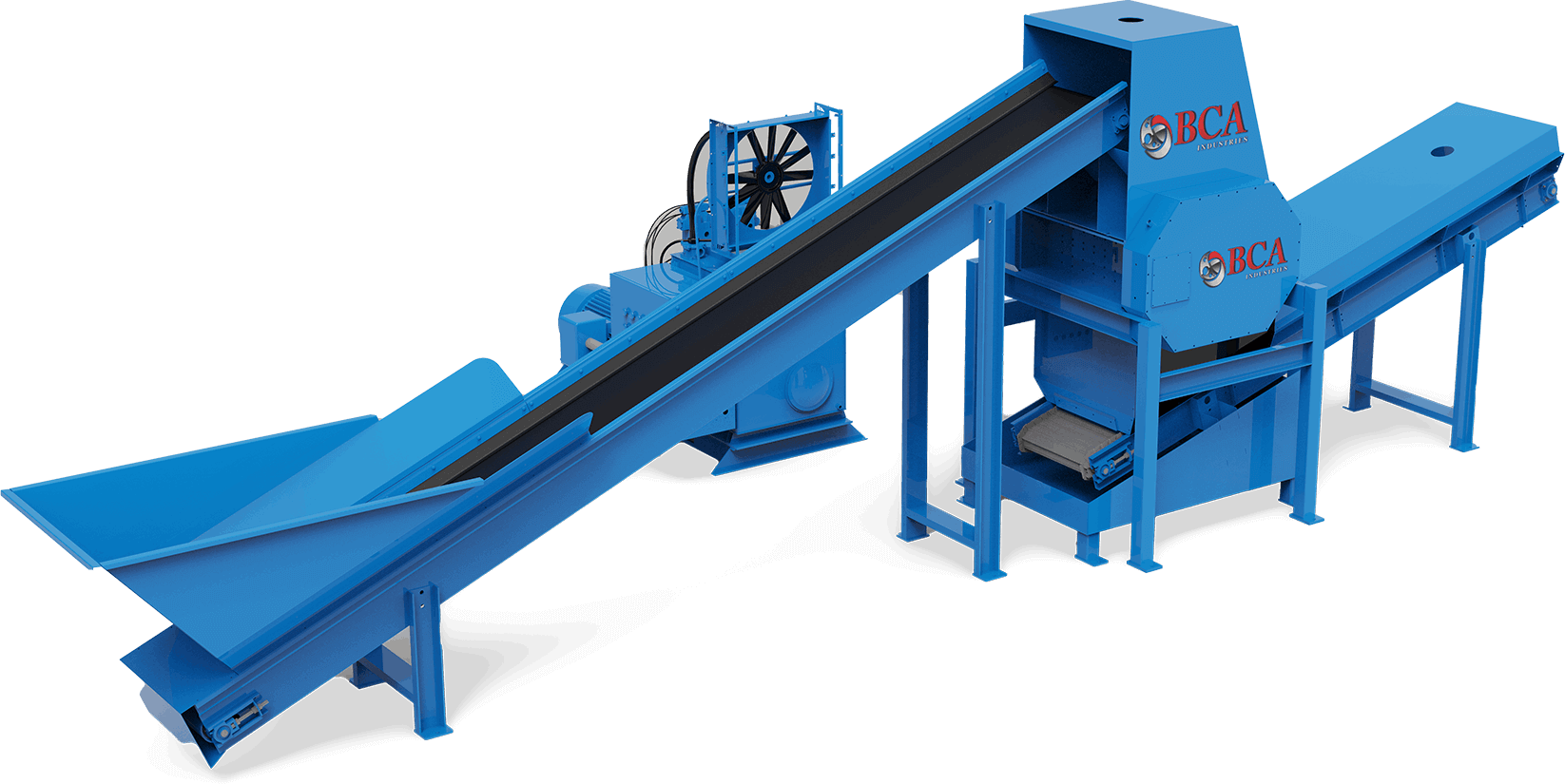

Stationary Plastic Shredders for Sale

Our stationary plastic shredders are ideal for dedicated recycling lines and large-scale manufacturing environments. BCA plastic shredding machines are built for continuous use, offering high throughput and reliable size reduction for plastic components, sheets and containers. A stationary plastic recycling machine is best for operations with fixed infrastructure and high processing demands.

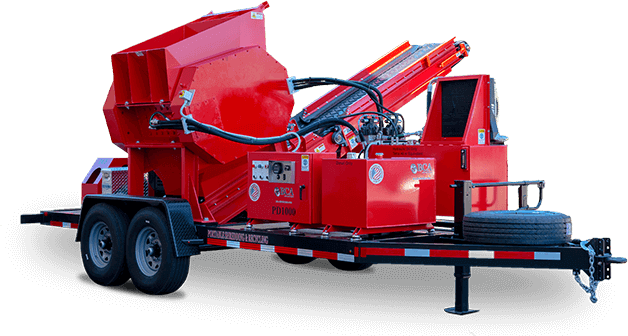

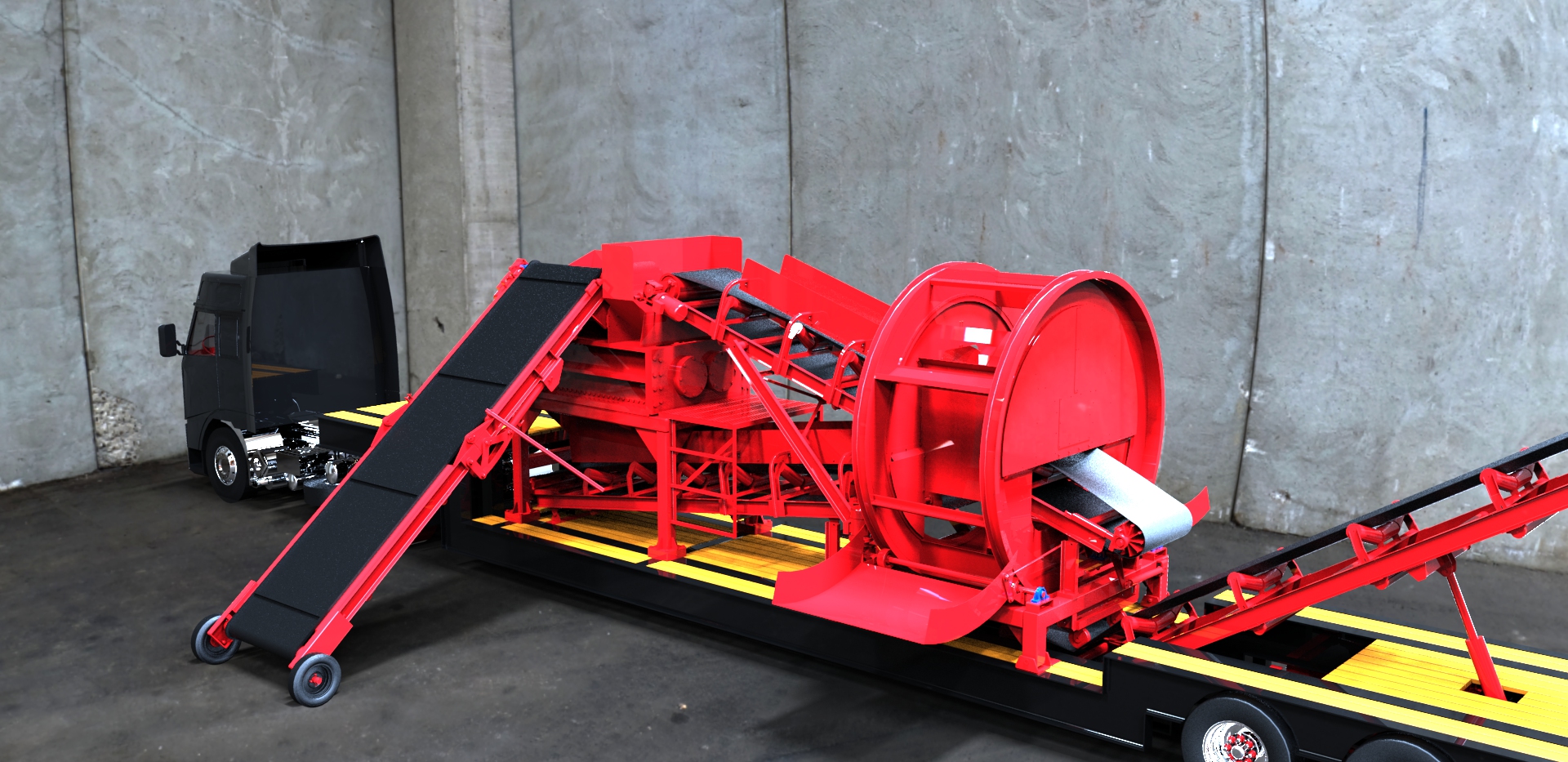

Portable Plastic Shredders for Sale

Our portable plastic shredders provide flexibility for companies with multiple facilities or temporary recycling sites. BCA mobile plastic shredders are easy to reposition and are designed for efficient on-site plastic waste processing. Whether you’re handling construction debris or satellite facility scrap, BCA’s portable shredding systems deliver consistent results with minimal setup time.

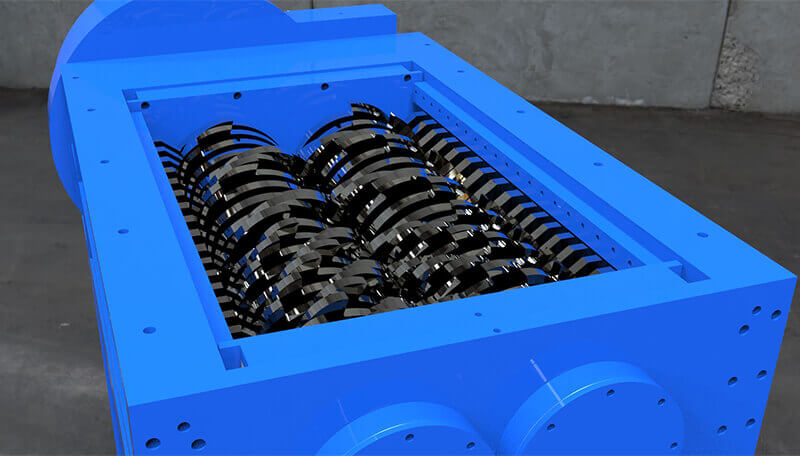

Patented Triplus® Knife System

Available on all BCA shredders, the patented Triplus® Knife System increases throughput and reduces energy use by combining three cutting stages—shred, chip and size—into one continuous pass. This screenless design delivers 85% correctly sized material on the first run and uses up to 150% less power than standard shredder systems. The Triplus® Knife System makes every plastic shredder more efficient, faster and easier to maintain.

How Plastic Is Recycled After Shredding

Shredding is the first step in turning plastic waste into reusable material. After processing through a BCA plastic shredder, the material is transformed and refined for resale or reuse. Here’s how it works:

- Plastic Flakes: Shredded plastic is reduced to flakes, which are used as feedstock for recycling or molded into new products.

- Plastic Pellets: The flakes are further processed into pellets used in containers, packaging and other molded applications.

- Composite Materials: Recycled plastic can be combined with other materials to create durable composite products for industrial use.

Plastic recycling machines from BCA Industries improve sorting efficiency, reduce landfill waste and support sustainable manufacturing processes.

How We Build Your Plastic Recycling Shredder

Each plastic recycling machine from BCA Industries is custom-built to meet your specific operational needs. We begin with a detailed consultation to understand your facility layout, material type and processing goals. Our engineers then develop a complete 3D model of your system using CAD software, factoring in load capacity, flow direction and power constraints.

Once approved, your plastic shredder is fabricated and assembled in-house. Before shipment, we fully test each plastic recycling shredder under load to confirm performance and integration readiness. Whether you’re building a new line or retrofitting an existing system, we offer:

- On-site installation

- Operator training

- 7-day support on all systems

Your plastic shredder is ready to perform at full capacity the moment it arrives.

Plastic Shredder Support & Maintenance

Reliable support keeps your plastic shredder running at peak performance. BCA Industries offers full lifecycle service to reduce downtime and protect your equipment investment. Our technicians work with your team to extend machine life and keep your recycling operation moving.

Our support services include:

- Shredder inspections: Identify wear early and keep your plastic recycling machine operating efficiently.

- Replacement Parts: Minimize downtime with quick access to in-stock components.

- Shredder Head Rebuilding: Extend the life of your equipment with expert-level reconditioning services.

Whether you’re processing post-consumer plastics or industrial scrap, we help maintain performance long after installation.

Replacement Parts for Our Plastic Shredders

BCA Industries supplies essential replacement parts to keep your plastic shredder system running efficiently. Each durable component is designed to improve material flow, separation and sizing across a wide range of plastic types, helping maintain performance across complete plastic recycling machine setups.

We offer:

- Custom Conveyor Systems: Improve material handling and loading consistency.

- Magnetic Components: Remove metal contaminants before or after shredding to protect equipment.

- Vibratory Screens: Accurately sort flakes and pellets by size for downstream processing.

- Trommel Screens: Handle high volumes of shredded plastic for effective material separation.

Plastic Shredder Leasing & Financing

Industrial plastic shredders for sale from BCA Industries are available with flexible leasing and financing options. Whether you’re scaling up your recycling operation or launching a new facility, we make it easier to access the equipment you need without a large upfront investment. Talk to our team about financing solutions for complete plastic recycling machines, portable shredders or custom-configured systems. We serve all major industries.

Contact our experts for more information or a quote on our industrial plastic shredders!